Description

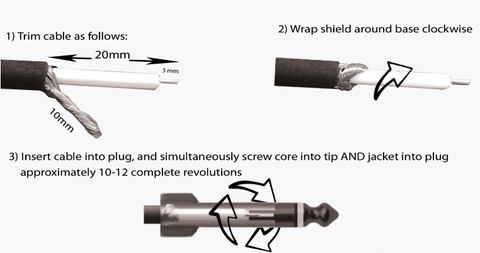

The inside of the tip of the SIS™ plug is carefully machined to have “threads” of a precise size and pitch. These threads cut and re-shape the soft conductor of the Monorail cable when turned around it several times.

When you push the prepared cable into the SIS plug, the soft copper will find the hole. When you turn the plug 1 or 2 times the harder brass core of the plug will catch and cut into the copper conductor. When you feel this happen you put the cap in place and screw the SIS plug into the cap.

This action turns the soft copper deeper into the SIS core – Mashes the ground up against the SIS body to make ground contact (airtight as the copper is deformed inside pushing air from the connection). This seals the red jacket at the exit tightly so that the cable will not come loose from the plug and the cap will not come loose from the plug body. When finished the tip/core connection with the Monorail is also air-tight and in many ways better than a soldered connection. If you unscrew the SIS plug and remove the Monorail cable you can see the soft copper has been shaped to meet with the SIS core.

Reviews

There are no reviews yet.